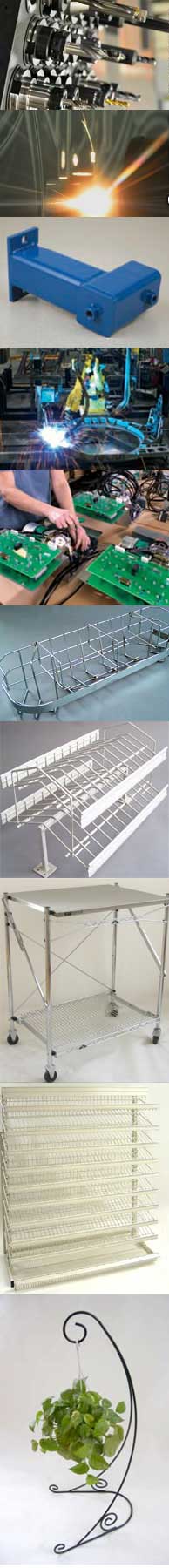

We start with wire, tubes or sheets and create your product designed, fabricated and coated to your exact specs.

Carbon, stainless steel and aluminum -

Medical, agricultural, turf care, food & beverage, merchandise display.

Fabrication -

Robotic welding,

MIG/TIG,

soldering,

brazing,

tinning, laser cutting,

electrostatic conveyorized paint line,

liquid and powder paint.

Coatings -

Powder, zinc, galvanized

zinc, nickel/chrome, satin nickel, electro-polish.

Design For Manufacturability -

Enhance product functionality,

Improve product quality,

Reduce overall costs to the customer.

Explore new materials,

Utilize current processes or develop new ones from digital pdfs to proto-type. Your requirements are identified through our "Design Input" process. Product design reviews continuously track these requirements throughout the life of the design process."Design Output" reviews confirm all requirements identified during the input process are met."Verification" and "Validation" is achieved when the design conforms to your needs, this includes testing under simulated or actual conditions.

Manufacturing, Testing, and Logistics -

"Best practice" manufacturing is followed from the start of project planning, into product design, and throughout the product life cycle.

We map processes to identify the most cost-effective approach.

We follow strict methodology to calculate, document, and implement the correct manufacturing process.

We increase productivity through constant evaluation and improvement of inputs (design, labor, material, equipment) to meet or exceed quality and quantity goals. The objective is to identify shared cost savings.

ISO 9001-2000 Certified

We're the experts you've been looking for:

Mitch Distler | mdistler@socket.net

210 Dalwhinne Waye |

Jefferson City, MO 65101 |

p: 573.636.2777 |

m: 573.680.9442 |

|

|